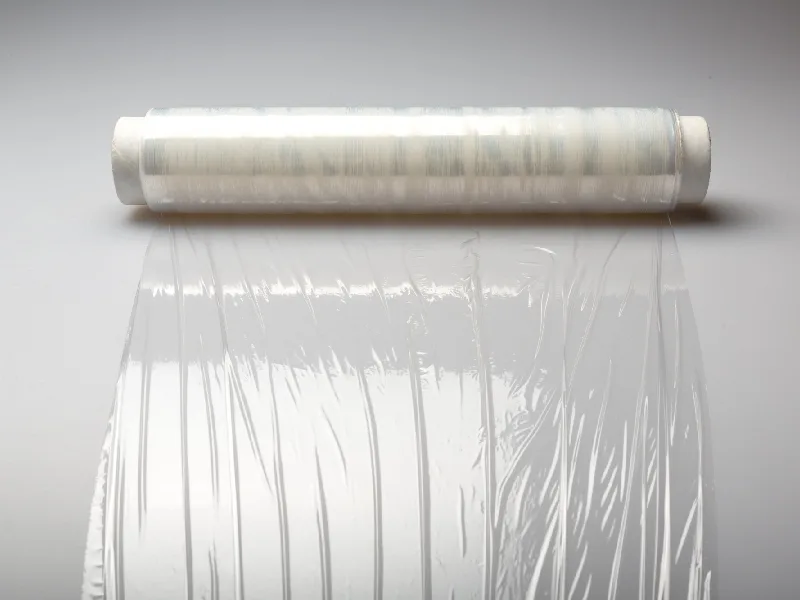

Stretch film — also known as industrial cling film — is a staple in the packaging game. Whether you’re stabilizing pallets in a warehouse or protecting goods in transit, this flexible plastic wrap plays a critical role in keeping things safe and secure.

But what makes stretch film really work?

It comes down to two core factors: thickness and stretchability.

Understanding both can help you choose the right film for your operation — and even reduce costs while improving efficiency. Let’s break it down.

What Is Film Thickness and Why It Matters

Stretch film thickness is typically measured in microns (µm) — one micron is a thousandth of a millimeter. The higher the number, the thicker (and generally stronger) the film. But don’t just assume thicker is better — choosing the right thickness depends on what you’re wrapping and how you’re wrapping it.

Factors That Affect Thickness Selection:

Product type & weight:

Heavier loads or items with sharp edges (like bricks or metal parts) need thicker film — think 30+ microns. Lighter cartons or smooth-surfaced products often do just fine with 17–23 microns.

Required protection:

For products exposed to bumps, dust, or moisture, a thicker film provides better defense.

Wrapping method:

Manual wrapping:

Operators using hand rolls often prefer thicker film (23–35 microns) to avoid tearing and make application easier. These films usually stretch less.

Machine wrapping:

Automated or semi-automated machines stretch the film significantly — thin films (12–23 microns) can stretch several times their length, which cuts down on material use. In this case, the **final thickness after stretch** (known as *gauge after pre-stretch*) is what counts.

Cost efficiency:

Thicker film costs more. The goal is to strike the right balance between strength and savings. In many cases, a thinner, high-stretch film delivers better results for less money.

What Stretchability Really Means

Stretchability refers to how much the film can stretch before breaking or losing its hold. It’s usually shown as a percentage — 200%, 300%, even up to 600%.

The higher the stretch percentage, the more surface you can cover with less film.

Why It’s a Big Deal:

1. Material savings

Let’s say your film has 200% stretch. That means 1 meter can be stretched to 3 meters (1 original + 2 stretched). That’s major savings — especially on high-volume lines.

2. Holding force

A properly stretched film has “memory” — it wants to snap back. This creates a tight wrap that holds your pallet together during transport. Even a thinner film with high stretch can deliver superior holding force.

3. Load stability

High-stretch film helps keep products from shifting, falling, or getting damaged in transit. That means fewer breakages, fewer returns, and happier clients.

4. Less waste

Stretchable film is less likely to tear or snap mid-wrap. That means fewer roll changes, less downtime, and better overall packaging performance.

Types of Stretchability

Hand wrap film:

Designed for manual use, these films offer lower stretch — typically around 50%–100%.

Machine wrap film:

Comes in two categories:

- Standard machine film: Moderate stretchability — about 150%–250%.

- High-performance stretch film: Made with advanced materials and tech, these can stretch up to 300%–600%. They’re ideal for operations using pre-stretch systems.

Pro Tip: High-stretch film only works to its full potential with the right equipment. If your wrapping line doesn’t support pre-stretch, you might not get the full benefit.

Finding the Right Balance: Thickness vs. Stretch

Here’s the kicker — a thicker film isn’t always better.

In fact, a thinner, more stretchable film can outperform a thicker one** if matched properly with your load type and wrapping equipment.

Smart Selection Tips:

Know your product:

Is it heavy? Fragile? Odd-shaped?

Think about distance, handling, warehouse conditions, and how it’ll be wrapped.

Test different options:

Run real-world trials with different film types. Don’t rely solely on specs.

Get expert advice:

Work with stretch film manufacturers or distributors who understand your machinery, load profiles, and industry standards. They can help you fine-tune your packaging — and your costs.

Invest in pre-stretch equipment:

If you’re wrapping high volumes, a pre-stretch system can pay off fast. It maximizes film performance and minimizes waste — meaning lower cost per pallet over time.

Raga Parsian: High-Performance Stretch Film at Scale

At Raga Parsian, we manufacture industrial-grade stretch film that’s built for real-world demands. We offer a full range of thicknesses and stretch profiles — from manual to high-performance machine wraps — all engineered for durability, flexibility, and cost efficiency.

We don’t just sell rolls — we offer tailored solutions for food, beverage, and industrial packaging lines.

What you get with Raga Parsian:

Consistent quality, batch after batch

Competitive factory-direct pricing

Expert guidance based on your equipment and load requirements Reliable supply and support

Final Takeaway

When it comes to stretch film, **thickness and stretchability go hand-in-hand**. One gives you strength, the other gives you efficiency. The smart play is finding the right combo for your load type, wrap method, and production setup.

By understanding these two factors — and working with a supplier that knows the ropes — you can cut costs, improve load security, and boost packaging performance across the board.

Want to optimize your stretch film use?

Reach out to the Raga Parsian team for a custom consultation — we’re here to help your packaging work harder and smarter.