When it comes to packaging, it’s not just about wrapping a product — it’s about preserving freshness, streamlining logistics, and boosting shelf appeal. One material that checks all those boxes? Stretch film. But not all stretch films are created equal. The two most common types — food-grade stretch film and industrial stretch wrap — are designed for very different jobs.

Let’s break down what sets them apart, and how to choose the right one for your business.

What Is Stretch Film, and Why Use It?

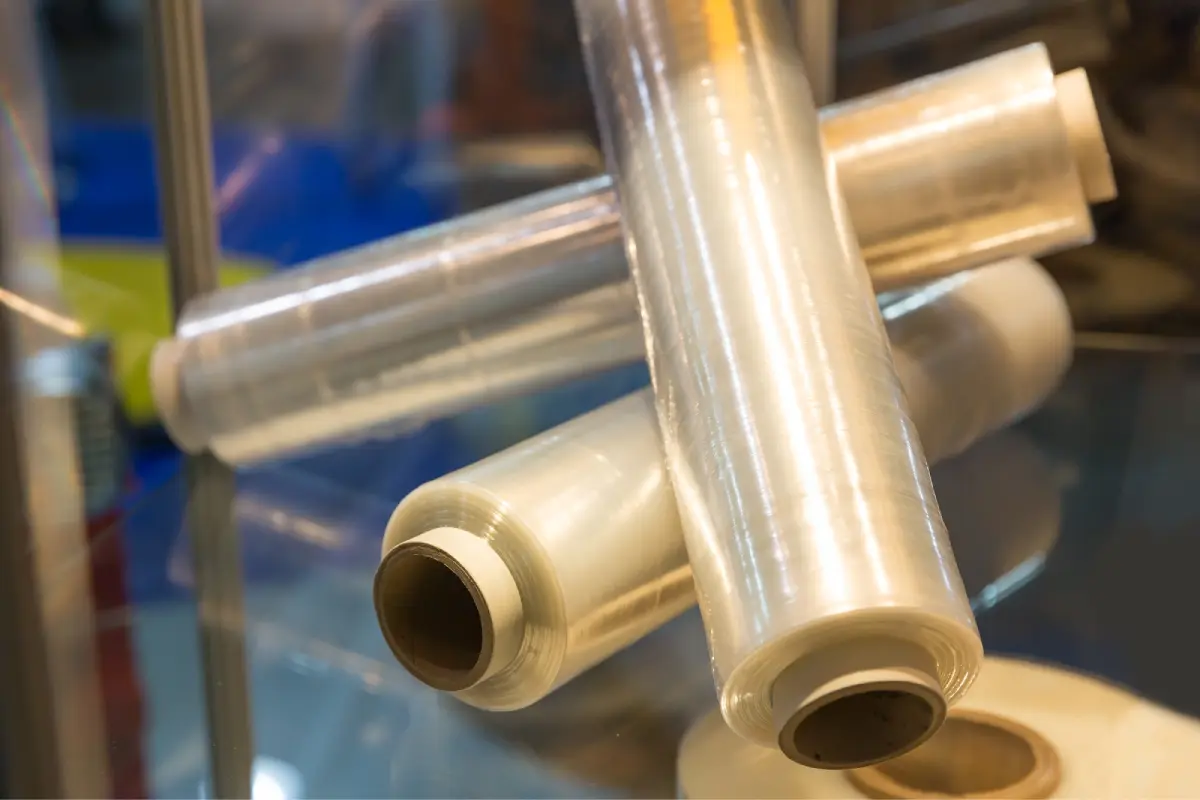

Stretch film (also called stretch wrap) is a flexible, transparent plastic used to secure and protect products. Thanks to its high stretchability, it tightly clings to the shape of the item, shielding it from dust, moisture, and handling damage.

From reducing packaging costs to speeding up operations, stretch film plays a key role in both food production and industrial packaging.

Key Differences Between Food-Grade and Industrial Stretch Film

Here’s how these two types compare:

1. Materials and Composition

The most important difference lies in the *raw materials:

Food-grade stretch film is made with high-quality, food-safe polyethylene. It meets strict hygiene standards and is safe for direct contact with meat, dairy, produce, and more.

Industrial stretch wrap, on the other hand, is built for durability. It often uses recycled or blended materials and includes additives to boost strength. It’s not intended for direct food contact, but it’s ideal for heavy-duty use.

2. Health and Safety Standards

Because food wrap touches the product directly, it has to be:

Odorless

Colorless

Free from harmful chemicals

Industrial film doesn’t have the same hygiene requirements, since it’s typically used for palletizing boxes, wrapping equipment, or securing non-edible goods.

3. Thickness and Stretch Capacity

Industrial stretch film is thicker and offers higher tear resistance, making it perfect for heavy or sharp-edged loads.

Food-grade film is thinner, but offers high clarity to showcase the product inside — essential for retail visibility and customer confidence.

Both types can be customized in terms of gauge, width, and length, depending on application.

4. Clarity and Appearance

When visibility matters, food-grade wins. It’s designed to be crystal clear, so shoppers and quality inspectors can easily view the contents.

Industrial wrap prioritizes strength over looks, so it may be slightly opaque — especially in thicker gauges.

Where and How They’re Used

Common Uses for Food-Grade Stretch Film:

Meat, poultry, and seafood

Fresh fruits and vegetables

Dairy products

Baked goods and confections

Deli trays and ready meals

Often used in supermarkets, food factories, delis, and restaurants, food-grade stretch wrap is typically rolled in narrower widths for manual or tabletop dispensers.

Common Uses for Industrial Stretch Film:

Pallet wrapping in warehouses

Securing boxes for shipment

Packaging industrial parts and tools

Automotive and construction materials

Industrial wrap is mostly used with machine stretch wrappers for high-volume operations in logistics, manufacturing, and export packaging.

Equipment Compatibility

Food-grade stretch wrap is designed for manual use or tabletop sealers, making it ideal for in-store packaging or small food producers.

Industrial stretch film is built for machine application — especially in high-speed settings where speed, consistency, and load stability matter most.

Raga Parsian offers stretch film options tailored to **both manual and automated packaging lines.

Pricing and Cost Factors

Industrial stretch film is generally more cost-effective per meter — especially in bulk — thanks to lower material costs and higher volume usage.

Food-grade film tends to be a bit more expensive due to hygiene requirements and premium raw materials. But the added safety and product protection make it well worth it for food applications.

Raga Parsian has optimized its production process to offer **competitive pricing** across both product lines — without cutting corners on quality.

Why Use Food-Grade Stretch Film?

Here’s what makes food-grade stretch wrap essential in the food sector:

* Keeps products fresh and hygienic

* Prevents contamination

* Extends shelf life

* Reduces food waste

* 100% recyclable and compliant with international food safety standards

Why Choose Industrial Stretch Wrap?

For non-food packaging, industrial stretch film offers:

* High puncture resistance

* Strong load stability

* Better protection during transit

* Less material waste

* Resistance to moisture, dirt, and handling damage

It’s a must-have in warehouse and shipping operations— especially for export packaging.

Custom Options That Work for Your Business

One size doesn’t fit all. That’s why Raga Parsian offers:

* Custom widths and thicknesses

* Options for manual or machine application

* Choice of tansparent or colored film

* Film rolls tailored to your industry and packaging equipment

No matter what you’re wrapping, we make sure it’s the right fit.

Final Thoughts

Both food-grade and industrial stretch film serve essential roles — but choosing the right one depends on your product type, packaging process, and safety requirements.

Raga Parsian is proud to be one of the leading stretch film suppliers in the region, trusted by food producers, factories, distributors, and logistics companies alike.

Need help picking the right stretch film for your operation? Get in touch — we’ll help you wrap smarter, faster, and better.